Motors, if they weren’t so wonderfully useful I would not have one.

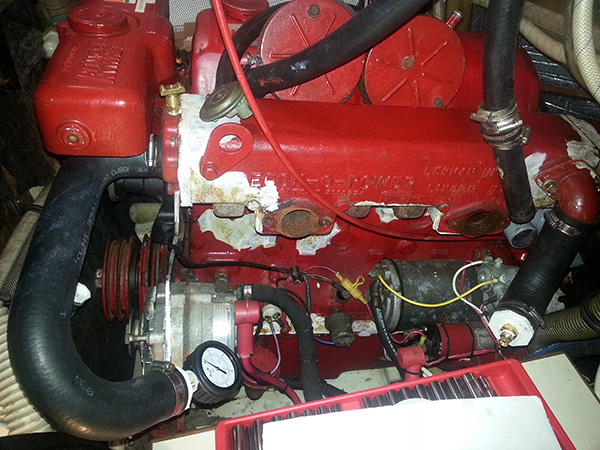

We love our 1976 Ford Lehman. The 80 horse power she puts out gets us in and out of harbors and makes anchoring a breeze. But relying on a motor so heavily has its downside, like if it doesn’t work. Fortunately, our Lehman has not let us down in our times of need. Don’t get me wrong, she’s broken down many a times but she always picks a moment when the coast is clear for a rest. She has pulled the old impeller disintegration trick, blown a hose or three, ejected the end caps from the heat exchanger, fried her starting relay, puffed copious amounts of white smoke out her tailpipe and warped the ends of her exhaust manifold. Most of the issues have been obvious, the signs are either waterfalls of water spraying throughout the engine room or an infinite moment of silence when turning the start key. But that last one, the warped exhaust manifold, was much more subtle.

Megan noticed it first, the coolant was not the Granny Smith green that is should be, it was black, and it was leaking out the over pressurization valve into the bilge. I had been a bad caretaker and neglected this critical component of the motor. Not sure how I missed it, I think I just didn’t want to see it. But there it was, an engine full of black coolant and a bilge to match. We had also been noticing that the exhaust was white in color coming out the tailpipe. My first thought was a blown head gasket. ARGGG! A BIG job to fix. But if that were the case the black stuff in the coolant would be oil and thank the stars it wasn’t. Some outside input led us to believe it was carbon from exhaust gases leaking into the coolant through an exhaust manifold gasket.

The exhaust manifold is a long chamber that collects the exhaust as it comes out of the cylinders and sends it on its way down a hose to the tailpipe. Surrounding this are chambers that coolant runs through. On either end of this forty pound chunk of cast iron are face plates that separate the exhaust and cooling chambers and prevent their contents from mixing. If one of the face plate gaskets fails the exhaust can push its way into the coolant causing it to, one, turn black, and two, become over pressurized and leak out the over pressurization valve.

We liked the idea of a leaky face plate gasket much better than a blown head gasket, they are cheaper and way easier to change. We drained the coolant (a chore in itself) and changed both gaskets. To confirm we had fixed the issue we bought some plumbing parts from Home Depot, sealed the ends of the cooling jacket and used our dinghy air pump to pressurize it. If the air pressure held we were good to go, if not, start over. It didn’t.

At this point we were worried the manifold had a crack in it and we’d have to purchase another one for a thousand dollars. Ouch. We decided to pull the whole manifold off the engine so we could have something really awkward and heavy to move around the boat… and so we could fill the exhaust chamber with water. The hope was that when the cooling jacket was pressurized with air and the exhaust chamber filled with water air bubbles would stream from the leak. A couple hours later, bubbles! And the manifold is not cracked!

The bubbles were oozing from the gasket we had just changed. Maybe I screwed it up? Off with the old gaskets, a little elbow grease to clean the metal faces, some goop to help the new gaskets seal, and bolt it all back together. Still bubbles. Awww, sadness. It dawned on us that someone had suggested that we take a straight edge to the ends of the manifold to check that they were flat. “If they aren’t perfectly flat they won’t seal.” Take it all apart, clean it, and voilà! the ends were warped!

Warped ends = a trip to a machine shop.

Instead of lugging the fifty-pound manifold around on trollies and busses for the hour and a half ride down to the machine shop we rented a car for the day. Good thing too because all the guys at the first shop shook their heads. But they humored us and called out the head machinist. He looked at the manifold and said, “Sergio at Motor Works, he’s the guy.”

As we walked through the garage door into Motor Works, a hefty young man that needed to purchase a belt wheeled a cart over to us, “put her here.” The shop was filled with car innards of every size, huge industrial machinery, the smell of motor oil and the clanging and grinding of metal on metal. A tall guy in a light blue mechanic’s shirt came over as well. We explained what we wanted to have done and one guy left. He came back with a short older man smoking a cigarette and wearing a tattered burgundy sweater, well-loved slacks and open toed sandals, Sergio.

The three of them stared at the manifold for a while, shifted to a new angle and stared at it some more. With the cigarette in the corner of his lips Sergio pointed at the manifold and said things like, “clamp it here” and “this end is clean.” I tried to encourage them by asking if it helped that the front edge was straight but my words just floated off into the clangs and churning motors around us. Finally, “Ya, we’ll give it a try for you.” Not very encouraging but better than “it can’t be done”. One of us asked if there was somewhere around that specialized in this kind of thing. “You can take it to someone else but you’ll have to bring it back here to fix it when they *%&! it up.” We were convinced. How long will it take? “Sometime this week, we’ll call you… maybe Friday.” It was Monday. We had hoped they could do it while we waited. Oh well. But to our surprise they called us at four that afternoon to say it was done.

When I went to pick up the manifold the next morning Sergio was wearing the same flimsy sweater and open toed sandals. Not your normal attire in a machine shop. He offered to use his torch to remove a few bolts that were stuck and while he heated, twisted and finessed the bolts loose we got to talking. He moved to San Diego after his time in the Korean War. “In the military I fixed tanks and jeeps and whatever else the troops brought back in shambles. We’d send out a tank in perfect working order and three hours later it’d limp back into the shop.” He seemed a disgusted. “They abused everything and didn’t seem to care.” It was hard for a man who loved motors to see such carelessness.

Sergio opened Motor Works in 1975. For a long time he did normal car repair and machining but as the industry moved towards disposable parts he began to specialize. “I often have to make parts from a chunk of metal,” he held up a block of steel, “Like on the Ferrari we are rebuilding now. Yesterday I made a new valve and rocker arm for it on my lathe.” He pointed to an antique machine with nobs and levers that filled the corner of the room. “I’ve had to specialize and find employees that want to learn a trade that is outdated. Today’s cars are disposable, when something breaks you don’t fix it, you replace it.” He looked worried as he explained that the guys he has working for him will be lucky if they can find a job in such a specialized field once Motor Works is no longer. His comment touched my heart, my dad has made his living as a craftsmen his whole life, first with leather and now wood. It seems that the majority of people look down on folks that work with their hands. But when you meet someone like Sergio, who can build a race car from a hunk of steel, or like my dad, who can build the sweetest sounding flute you ever heard from a tree branch, it’s impossible not to marvel at what human hands can do.

Back on Orion we gooped the gaskets, tightened the bolts, pressurized the jacket and the manifold was healed! The next day the motor was purring like a kitten after a bowl of milk. But that dang white color in the exhaust persisted.