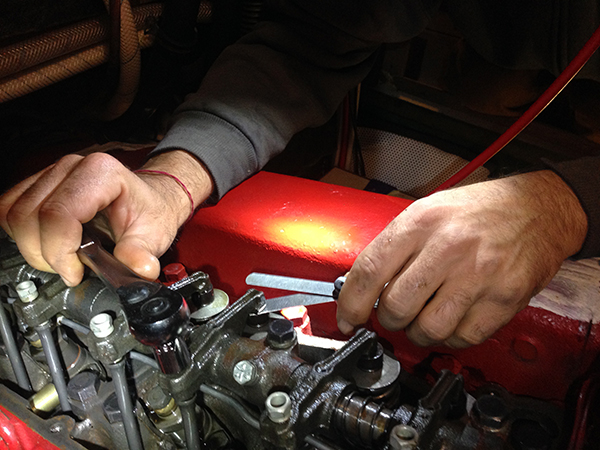

Many of our friends and family have asked us just what we were doing in San Diego that delayed our exit for a whole two whole months. Well we chose a lovely location to ensue the full time jobs of overhauling our engine as well as a myriad of other boat projects. Our boat is 39 years old and the motor, as well as many of her parts, are original. She is a fine workhorse of a motor that simply needs to be maintained to keep healthy and thriving. We did quite a bit before leaving, but we realized that since everything was already taken apart this was our best opportunity to do the whole shebang. Once we dismantled our coolant system we replaced all coolant hoses, replaced the heat exchanger (that had already broke and been braised back together on a previous trip), replaced pit cocks, changed the fan belt, replaced the freshwater coolant pump, and flushed the system around eight times to remove the black sludge from the exhaust leak. All this while troubleshooting our exhaust manifold leak, changing all its gaskets, and getting the ends machined so they were flush for the seals. We also replaced the stop solenoid, adjusted the engine valves, got our injectors rebuilt, and retorqued the head bolts. We then cleaned all the salt off the motor, covered her in Corrosion X, and did some rust-busting after the waterfalls of saltwater in the engine room incident on our way down.

We used this time to remake our lazy jacks, service our outboard dinghy motor, make a emergency tiller for the hydrovane auxiliary rudder, install our radar reflector, and install a saltwater foot pump in the galley. We installed our SSB radio and the associated antennae and grounding system, and we learned how to use it to send emails and get weather faxes while at sea. Being at anchor here was our first chance to ground test our wind generator and we found that it was not functioning properly. Troubleshooting showed it to be a manufacturing defect, so we sent it back to manufacturer to be repaired and waited for its return. We fixed our hydrovane after it became jammed, and we patched about ten holes in our dinghy that all came from one sad day tied up next to something evil.

It was a busy time, and while it was not swimming with whale sharks off a deserted island, it was a great learning experience. Now after all that we both have even more trust in lovely Orion and all her parts as well as our abilities to deal with issues as they occur. The lesson of not being in a hurry was beaten into us enough times, over enough days, that maybe just maybe we’ve learned a bit of it.